本帖最后由 QH912 于 2014-9-25 21:01 编辑

Architects(建筑事务所): Vo Trong Nghia Architects

Location(项目地点): tp. Tan An, Long An Province, Vietnam

Architect In Charge(建筑负责人): Vo Trong Nghia, Masaaki Iwamoto, Kosuke Nishijima

Year(年份): 2014

Photographs(摄影师): Hiroyuki Oki

Contractor(承包商): Wind and Water House JSC

Construction Cost(建设费用): 4000USD per unit(4000美元/住宅单元体)

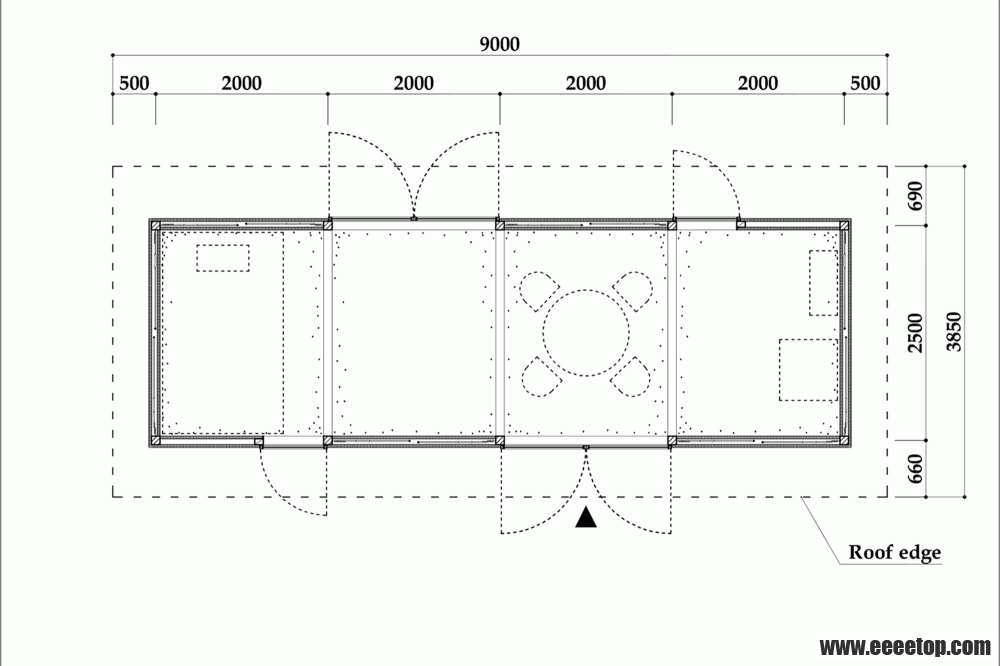

From the architect. People in Mekong Delta, with an average income under 100 USD per month mainly live in cheap temporary houses. Ironically, poor structures result in high maintenance fee. Therefore, low-cost but permanent house is an urgent social issue here. With the given situation, the aim of “s house” project is to provide stable but lightweight, permanent but affordable homes within a budget of 4,000 USD per unit (30 sqm). 以下信息来自建筑事务所:居住在湄公河三角洲(位于东南亚——译者注)的人们平均月收入不足100美元,大多生活在廉价临时住宅中。具有讽刺意味的是,低劣的房屋结构带来了高昂的维护费用。因此,廉价而耐久的住宅成了当地迫切的社会问题。在所给境况条件下,“S住宅”方案意在提供稳固却轻质、耐久又经济的房屋,预算在每单元住宅(30平方米)4000美元以内。

时间轴

The first phase of the project started in 2012 with a steel frame prototype. Since 2013, in pursuit of higher stability and thermal comfort in a tropical climate, a new prototype with precast concrete frame was designed and two houses is constructed in Long An Province. 项目的第一阶段已于2012年开工,采用钢架结构。自2013年以来,为实现更高的稳固性及在热带气候环境中的热舒适度,设计出一种新型预制混泥土框架结构,并已实践于隆安省(位于越南,区属湄公河三角洲,北与柬埔寨相邻,西南接同塔省,南邻前江省,东邻胡志明市——译者注)的两座房屋当中。

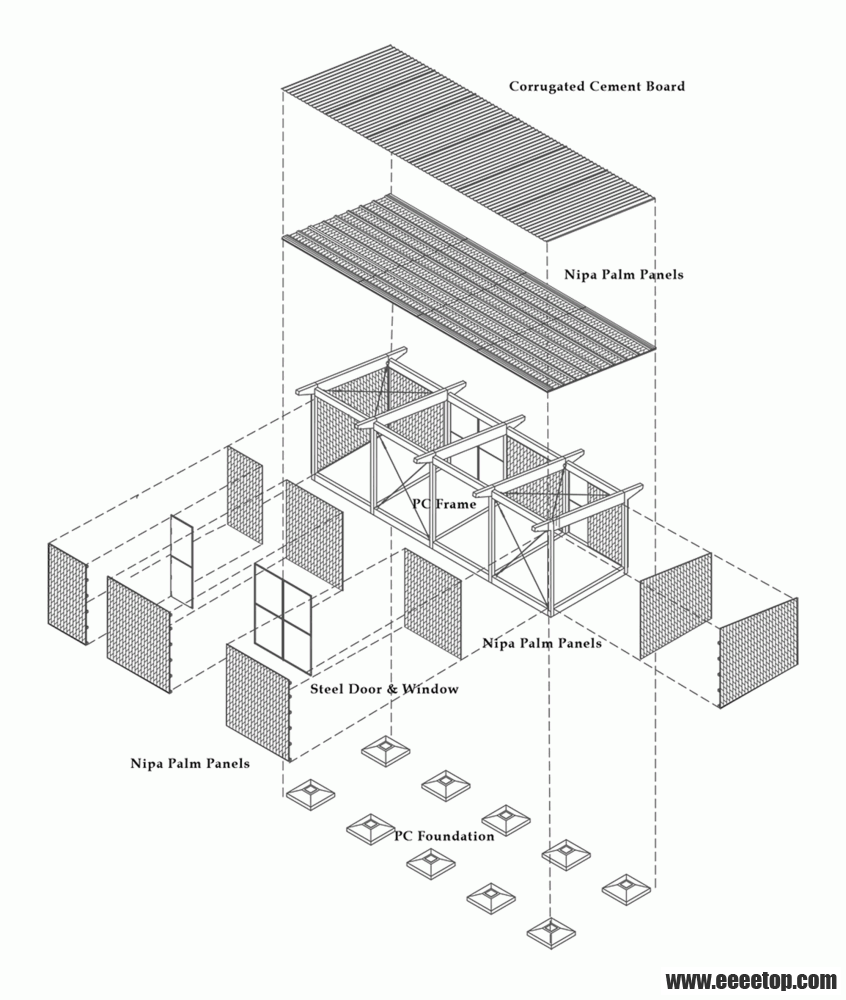

轴测图

The concept of the second prototype is to combine modular components and DIY strategy. Prefabrication helps control quality and cost, and future mass production. Precast concrete frame and foundation guarantee predetermined stability and accuracy. The lightweight structure allows smaller foundation and transportability by small boats, since waterways are still the dominant transportation in Mekong Delta. Light frames with simple bolted connection also encourage dwellers to participate in construction. Locally sourced, finishing materials can all be assembled and replaced easily by dwellers and neighbors for the future change or extension.

第二种结构型的概念是将模数化构件与自助策略相结合。预制房屋构件有助于控制品质与成本和实现未来的大规模生产。预制的混泥土框架和基础可保证业已决定的稳固性和精确度。轻质结构可缩小基础故通过小船即可运输,因为水路仍在湄公河三角洲地区的运输方式中占主导地位。通过简易螺栓连接的轻型框架也能促使居住者参与到搭建的活动中来。通过就地取材,建筑的装饰材料均可由屋主和邻居们轻易搜集和更换,便于未来的改建或扩建。

自主建造过程

To cope with harsh weather of the region, the project utilizes passive design strategies. Nipa palm and corrugated cement is combined to form a “double roof”, it helps protect dwellers from excessive rain while providing sufficient thermal comfort. Polycarbonate panels allow natural light to enter and reduce the need for artificial lighting, while the gap between the roof and walls is to promote natural ventilation. Since nipa palms cost next to nothing in Mekong Delta, it is not only a familiar material to the locales but also in harmony with the surrounding scenery. 为了应对该地区严酷的气候,方案采取被动设计策略。日本棕榈树与波纹水泥结合形成“双层屋面”,使居住者免受暴雨侵袭并保证适宜的热舒适度。聚碳酸酯面板将自然光引入室内以减少人工照明,屋盖和墙体间的缝隙促进了空气流通。在湄公河三角洲地区日本棕榈树材料的成本最低,因此它不仅是当地人熟悉的材料,也与周围环境相协调。

剖面图

After construction of the second, the third prototype with higher durability, lighter structure and more reasonable components is on progress. 二期工程结束后,第三种更为耐久轻质且合理的结构正在发展当中。

调研

设计理念

组成部分

总平面图

。

平面图

立面图

节点分析图1

节点分析图2

原文标题:S House / Vo Trong Nghia Architects

|